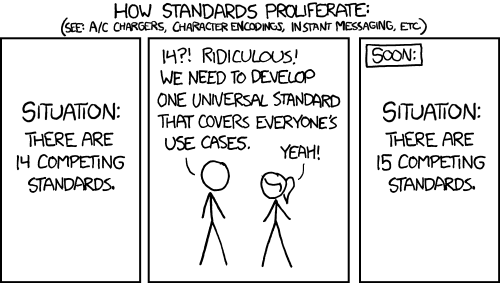

The Growing Maze of Data Protocols

When data is exchanged between two devices, this transfer requires a set of rules. The rules governing such transactions are called data protocols. For monitoring machinery, these protocols are essential for communicating with sensors and devices. As more devices and sensors enter the market, each comes with its unique protocol for data communication.

This diversity creates a complex mesh where data becomes harder to manage and utilize effectively. The creation of many protocols, including both open and proprietary standards, often centers around concerns such as security, compatibility, and more. However, this leads organizations to invest in supporting all these protocols to capture such data. (In another post, we will dive into how to utilize captured data.

What if we reuse existing sensors and their protocols for condition monitoring?

Many organizations already have sensors (i.e., devices) deployed for other purposes. One common use is control, where the operation is managed to achieve a certain level of production. For instance, if sensors that were used for control were to be repurposed for machine condition monitoring, the following questions are critical:

- Are the sensors suitable for condition monitoring?

- For instance, there are many types of vibration sensors, which are only suitable for heavy machinery.

- How can we address the cybersecurity challenges of using this sensor?

- What is the cost of using the data protocol if the protocol is proprietary?

- Are licenses still available for sale?

- Do you need to upgrade to the latest hardware or software to access the protocol?

- Are licenses still available for sale?

Our Solution: A Versatile Condition Monitoring System

At ADG, we recognize these challenges and have developed our solution with versatility and comprehensive protocol support in mind. Our product provides secure and robust support for most existing data protocols. We recommend purpose-specific sensor devices and then collaborate through the integration process. This ensures that the best of the technology is utilized without compatibility issues.

To learn more about our Machine Condition Monitoring solutions, contact us.