Condition Monitoring for Biogas Engines

Biogas engines convert organic waste into clean, usable energy. To ensure optimal performance, efficiency, and longevity, engine manufacturers usually recommend a routine maintenance schedule. However, routine maintenance cannot detect defects or predict failures in real time.

"Prevention is better than cure."

by Desiderius Erasmus

Real-time monitoring is possible through intelligent condition monitoring. This approach provides continuous assessment of the engine's health by tracking parameters such as vibration, temperature, pressure, oil quality, and gas composition. For instance, oil degradation can be monitored to detect potential issues before they lead to failure.

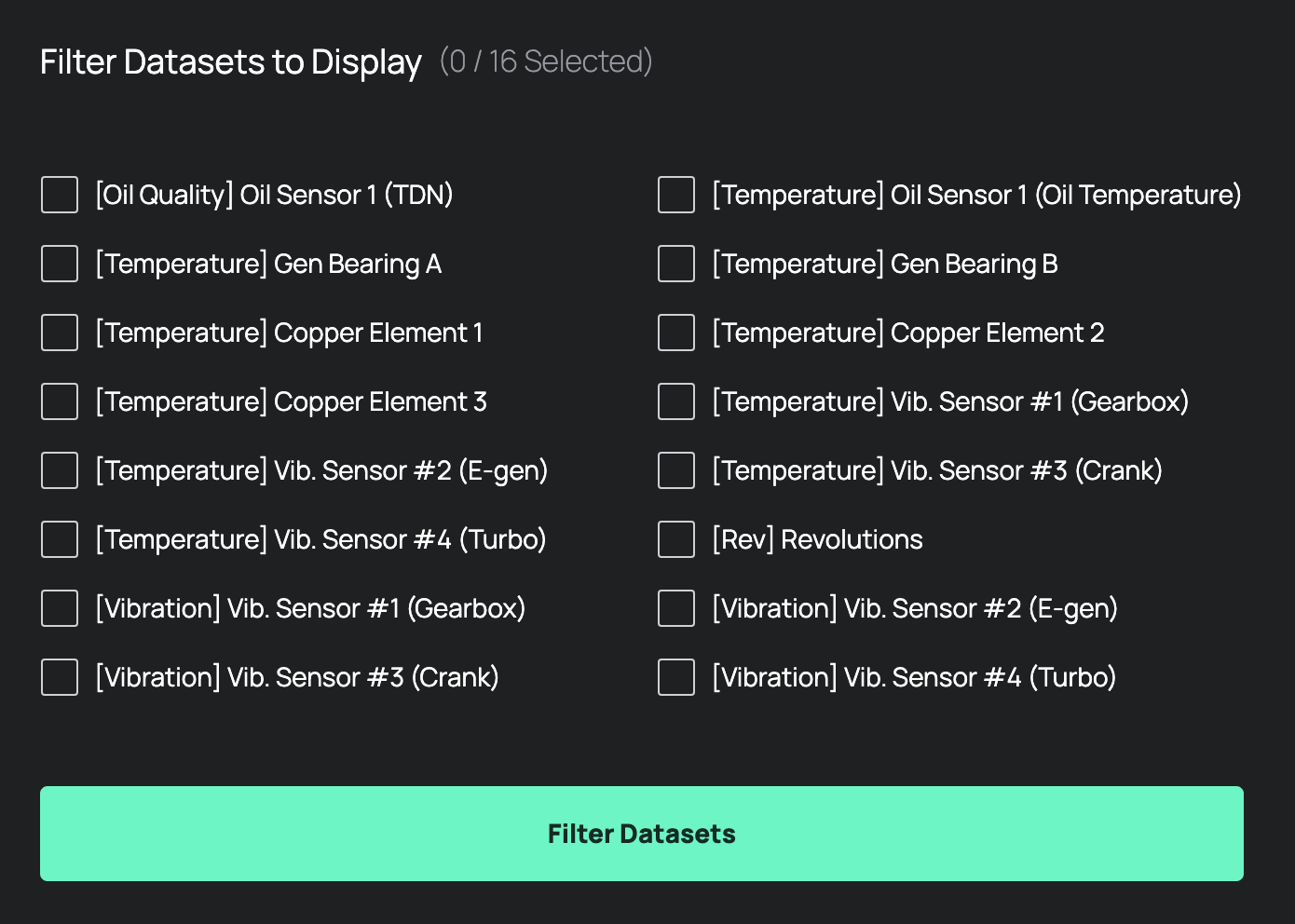

Not excluding many other related datasets can be monitored:

Utilizing all these parameters helps shift operations from reactive responses to proactive strategies that anticipate future events. Such preventive maintenance minimizes downtime and reduces costly repairs.

Do you think your organization could benefit from real-time monitoring? If so, we invite you to contact us to learn more about our condition monitoring solutions.